In the last 100 years there have been mechanical advancements that have completely changed agriculture in America. The tractor, combine, and centre pivot irrigation system are some that would come to mind but the marvel of hydraulics is often overlooked and taken for granted. That is until it stops functioning.

Hydraulics has been integrated into most every aspect of farming. It has allowed more work to be performed by one man than an entire family could accomplish in a bygone era. In many ways hydraulic oil is the most important fluid on the farm.

Basic theory

A hydraulic system works under the principle that a liquid is considered non-compressible. Other facts about hydraulics are: resistance to flow is the only way to create pressure in the system; and that energy created under pressure will yield either work or heat.

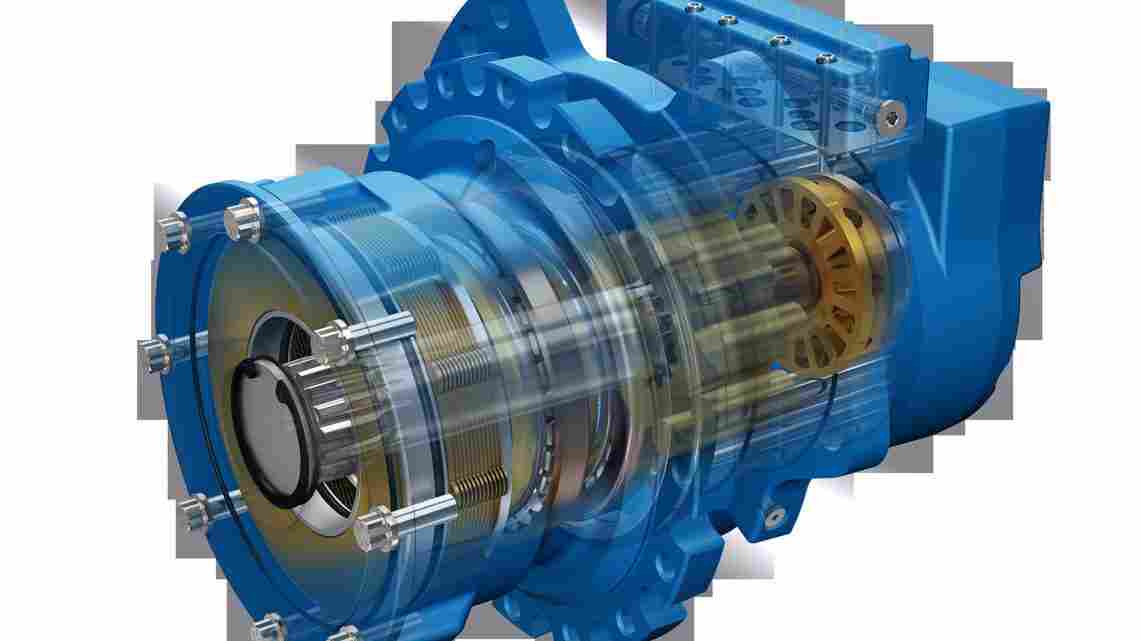

The main mechanical component of the hydraulic system is the pump. It converts mechanical force into fluid energy.

There are two basic pump design theories: non-positive displacement and positive displacement. Only positive displacement (each revolution delivers an exact amount of fluid) pumps are used on hydraulic systems. The hydraulic pump can be considered either a fixed displacement or variable displacement style. Within that classification there are also gear, vane, and piston pumps.

A fixed displacement pump moves the same volume of hydraulic oil with each cycle. Only the speed of the pump modifies the output.

The variable displacement pump can alter the volume of hydraulic oil it moves with each cycle even if the operating speed stays the same. This design is employed in applications where a specific pressure or flow must be maintained.

It must be remembered that no hydraulic pump creates pressure, only a flow of oil. Pressure is the result of a restriction to flow.

The methods used to control the flow of hydraulic oil are open-center system, closed-center system, and a load-sensing system.

Most early hydraulic systems used on tractors were open-center designs. As more functions were added that progressed to closed-center and finally a load-sensing system.

With an open-center system the pump produces a continuous flow that must be returned to the reservoir when the cylinder or other actuator is not being moved. This is called standby. During this time flow volume is high and the pressure is low. When flow is directed via a control valve to a cylinder, the oil volume stays constant but the pressure is increased to the level necessary to perform the work or to a relief valve setting.

When the control valve is released the fluid remains trapped in the cylinder and the workload is supported. The pump pressure goes down and flow increases.

In contrast, with a closed-center system a central source of fluid power is used to operate multiple functions.

Pump displacement and thus flow changes to meet the demand required. When no function is required, oil flow is blocked at the control valve. When one or more control valves are opened the pump automatically adjusts the delivery rate (volume) to satisfy the demand. Pressure to the valves will be maintained as long as the pump volume is sufficient to meet the demand.

Today, it is common to find a load-sensing system. It is a modification on the closed-system design. It permits stand-by pressure to be low when the control valve is in neutral. When the operator moves the control valve, flow is designed to maintain a pressure slightly higher than the highest pressure needed in the system. It regulates flow based on the pressure required to move the load rather than based on the pump output.

The load-sensing hydraulic system is the style most commonly found on modern farm equipment.

The all-important oil

Hydraulic oil is a highly refined petroleum based product with additives so it may become a suitable working fluid.

It is been estimated that 70 percent of the hydraulic failures or problems with farm equipment is rooted in the use of the wrong fluid or the system contains dirt, moisture or other contaminants.

The hydraulic fluid has multiple jobs other than just performing work. It must provide lubrication for moving parts, be stable and have a long service life, protect parts from rust and corrosion, resist foaming and oxidation and be capable of separating itself from air, water and other contaminants. Hydraulic oil must also maintain a designed viscosity while operating in a wide temperature range.

Viscosity is a fluid’s resistance to flow. It is the thickness at a defined temperature set by the Society of Automotive Engineers (SAE). All petroleum-based oils tend to thicken when cold and become thinner when heated. If the viscosity is too low (thin), leakage past the seals of the system is very probable. In contrast, if the fluid is too thick (high viscosity), sluggish operation of the hydraulics is seen along with an additional power drain on the equipment’s engine. The viscosity also impacts the lubrication function of the hydraulic oil.

Viscosity is determined by measuring the time required for 3.66 cubic inches of oil at a temperature of 210 degrees F to flow through an instrument known as a Saybolt Viscometer or a Kinematic Viscometer.

In contrast, a fluid’s viscosity index is the ability to change thickness with temperature. It is considered to have a low viscosity index if it becomes very thick at low temperatures and very thin when heated. A fluid with a high viscosity index remains relatively stable in regard to thickness as it is heated or cooled. It is important that you only use a quality hydraulic fluid that has a high viscosity index for proper function and long equipment life.

Farm equipment hydraulic systems are fitted with components that have very tight and exacting tolerances. Due to this the lubricating qualities of hydraulic oil are paramount to long life. Good oil will be able to cling to close fitting parts even under high temperatures. In addition, many farm tractors use the hydraulic oil to lubricate the transmission. Low-quality hydraulic oil will provoke excess wear in the hydraulics and transmission.

An easy path to long life

The steps to ensuring a trouble-free hydraulic system are quite basic. It needs to be recognized that hydraulic oil does wear out over time and needs to be changed. The additive package becomes consumed and by the environment the equipment operates in, dirt and moisture will infiltrate. This will allow wear and corrosion of key components to accelerate along with a deterioration of all seals and gaskets. In addition, parts may become mechanically bound and stick, especially in control valves.

The best method is to follow the manufacturers recommendations for complete fluid change and service intervals.

When purchasing hydraulic fluid make sure the brand meets or exceeds the requirements for your machine and is not just low-cost oil. Most if not all farm equipment manufacturers have application specific requirements for the oil. Even though you may save a few dollars with a low-grade product in the long run it will cost you. The same goes for hydraulic filters —- good ones are expensive but are much cheaper than a major repair.

Though many farmers do not like to hear this, I always suggest using the equipment manufacturer’s hydraulic fluid brand. There is no industry standard for hydraulic fluid and thus, only the machine designer knows the chemical composition required, regardless of what a no-name brand may claim.

Listen and pay attention to the way the system operates. It will tell you that something is going wrong long before a major problem occurs. Is it lazy, moans or no longer wants to lift the same load? That means something.

Proper service intervals are meaningless if the user is sloppy with keeping the fittings clean when connecting implements. Always use the dust caps and wipe off any fitting or service port before opening up or closing. Keep the hydraulics system exterior clean by simply washing it with a hose — dirt left around seals and dipsticks will eventually work into the fluid.

When it comes to storing fluid keep the can(s) in a dry place that has a minimum of temperature variation to avoid condensation from forming and polluting new oil. Do not over buy hydraulic oil — get what you need for service and top-off and replace it when necessary.

With a small amount of care the hydraulic system on your equipment will be the most reliable farm hand you can ever have!